Tolerance is known for flexibility and giving, patience and self-sacrificing. Engineers also make the use of tolerance on dimensions in all of their building and construction projects. Engineers place tolerance on dimensions for the construction of more stable and sturdy projects such as huge towers, bridges, and roads. Buildings such as hospitals, malls skyways and much more are strong, dependable and reliable just because engineers have utilized dimension tolerance during the construction process. Tolerances are used on dimensions in order to enhance the quality of a project. Engineering tolerance is limits of variation on physical dimensions. Engineering tolerance is also a permissible limit in measured value or physical property of a material manufactured object. In mechanical engineering, tolerance is space between bolt and nut. In other words, we can say that engineering tolerance is consideration of dimensions, properties or conditions which with some variation would not be able to affect the functioning of a system, machine or structure. So why do engineers place tolerances on dimensions?

The reason engineers place tolerances on dimensions

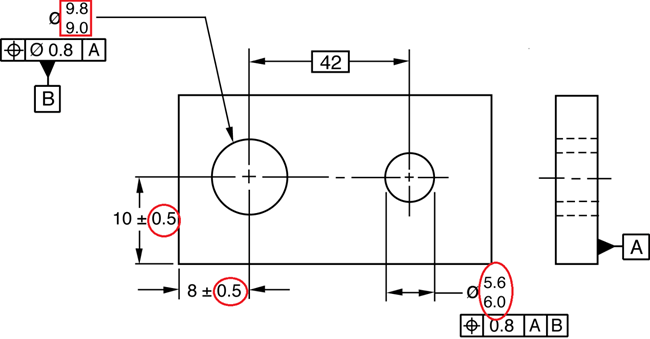

If an engineer leaves dimension without tolerance, it will result in improper fits, delay, and high cost. Tolerance is a total amount for which a particular dimension is permitted to vary. It is the difference between maximum and minimum limits. Tolerance is giving acceptable deviation for a given dimension. Engineers place tolerance on dimensions because it provides the opportunity to manufacture individual components in different companies at different locations and enable engineers to assemble them successfully. This article will answer the question, why do engineers place tolerances on dimensions, by considering some of the significant benefits.

Advantages of Tolerances

- Tolerance gives a significant number of benefits to manufacturers as well as engineers. If dimensional tolerance is used correctly, it will make the production possible as per needs and desires of the engineers. Engineers use tolerances because it reduces cost by making things as desired whereas unnecessarily tight tolerance is expensive. For example, if you place a ±0.0002 tolerance on a dimension instead of ±0.002 if it is not needed for the functionality of the product, then it will result in an unnecessary extra cost to produce or manufacture.

- Tolerance on dimension is the total amount that a particular dimension is allowed to vary. It is the difference between minimum and maximum and offering a large number of benefits. Engineers place tolerance on dimension to reduce the time and cost of manufacturing of the particular

- Tolerence enables engineers to manufacture a particular design in different companies at different locations with less production cost and less time. Engineers place dimension on tolerance to enhance performance and reliability of the product. Here the term product refers to buildings, malls, roads, Performance of the product deals with primary operating characteristics of a product and Reliability is the likelihood that the product will not fail within the particular time period it is requred to work. Tolerances are essential to ensure performance and reliability of the product

- Another significant benefit of placing tolerance on dimension is that proper use of tolerances shifts the liability of making parts correctly to manufacturers. Engineers are only responsible when the parts are manufactured within tolerance and don’t fit. Therefore, placing a suitable and appropriate amount of tolerance is essential for enhancing the quality of the product and for reducing cost, time and liability of the designers.

- Tolerance on dimension also enables the engineers to get the desired product. It allows manufacturers to manufacture what has been designed. Tolerance on dimension reduces the chances of error. It also decreases the risk of uncertainty and ambiguity in measurements. Dimension tolerances allow engineers to make parts correctly. Use of tolerance appropriately saves time spent in coordinating with manufacturers, circumvent the design issues and reduce unnecessary costing. Dimensional tolerance is as important as geometric tolerance in fully defining parts.

Conclusion

Going back to the question asked in the beginning, Why do engineers place tolerances on dimensions? Engineers place tolerance on dimensions to allow variances in an acceptable range in order to make a product function properly. The amount of tolerance depends on the degree of variations in a particular object. In the field of science and mathematics, engineers are using tolerance on a regular basis. In a nutshell we can say that in field of engineering, tolerance is one of the most significantly needed elements to enhance the quality and performance of the product.