Hoshin Kanri Tools and How They Are Used

Hoshin can be well-defined as ‘the direction of a needle’ more like a compass while Kanri can be defined as ‘controlled reasoning or controlled logic’. In short words, Hoshin means ‘direction’ while Kanri means ‘administration’ and when used together, they ask the question “How can we make sure to [...]

What Are the Gemba Walk Questions to Ask

Definition of Gemba Walk The Japanese word ‘Gemba’ means ‘a place of activity’. One of the lean principles, the Genchi Genbutsu states that in order to really comprehend your processes you need to see the processes on Gemba. The goal of the Gemba walk questions are to motivate the [...]

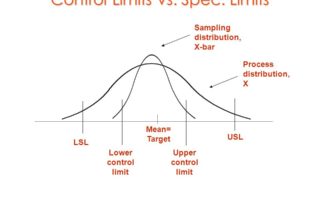

What Is the Difference Between Control Limits and Specification Limits

Control limits are indicators of the disparity in the performance of an operation. This is the real time value on which the process is operating. Specification limits on the other hand are the targets or goals set for the products or the process by the market performance, as an [...]

What Is the Andon Light Colour Meanings

The Japanese term Andon means signal light or paper lantern. In Lean management, Andon is used as a visual management method to quickly alert anyone to the status of an operation. Andon is a important lean tool as it is useful in the smooth running of operations. Andon can also [...]

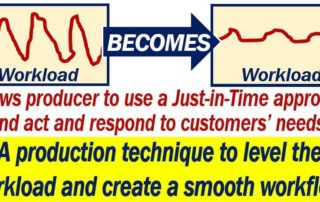

Heijunka Board Examples Used in Manufacturing

Heijunka (pronounced Hi-JUNE-kuh) is a Japanese word that signifies "leveling." When executed accurately, heijunka efficiently and without flurry enables business to take care of demand while decreasing waste and interpersonal procedures. As per numerous Lean experts, heijunka is better accomplished as a later-stage implementation in Lean organizations, long after [...]

What Is the DMAIC Process and How Is It Used

The DMAIC (Deh-May-Ick) process is a very compelling, data-driven, five-step approach to continual improvement. The fundamental objective of DMAIC is to take out costly variation from business and production processes. So what precisely is DMAIC? The acronym speaks to the following five steps: Define Measure Analyse Improve Control This [...]