The term Lean comes from manufacturing practices where it was initially used to improve effectiveness in production. It is now used across a lot of industries including software houses, manufacturing industries, business companies and even the construction industry. This method is for continuous improvement in work and management. It is a simple yet quick way to make an impact when it is implemented properly. In a book named “The Machine That Changed the World” Womac and Jones have described the famous 5 principles of lean production. These principles of lean production are used to make the workplace better and efficient. Here we are going to define each principle of lean production for better understanding. Have a detailed look:

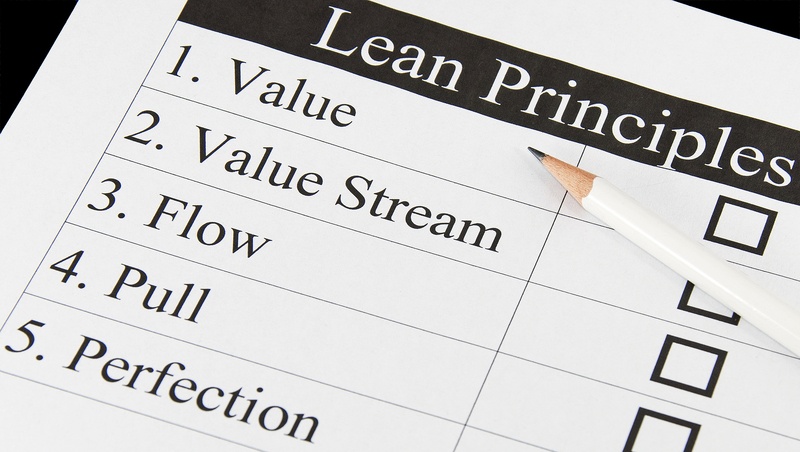

The 5 Principles of Lean Production

Define Value

The very first step of understanding all 5 principles starts from understanding value. What defines the value of a brand? It is the value that a customer or a client is willing to pay for in exchange for a product or a service by some particular brand or a company. In any industry, it is vital to discover the actual needs of your customers or clients. Sometimes, clients or customers don’t know what they want. Suppose in the technology sector, people just go to a certain brand to buy phones even though they are not sure about the features of a new phone. But there are some techniques like interviews, surveys and many other things that can be gathered through web analytics which can identify your customer values. Gather all the intel and make products that your customer wants.

Map Value Stream

The second of the 5 principles of lean production is to map out all the factors that can contribute to achieving customer value. Start with the gathered intel, make references to the points that can be helpful in achieving value. Anything else that is of non-value should be excluded but at the same time, there are a few necessary things that come along with that. It is time that you figure out which things are necessary, and which are not. If there are some unnecessary baggage’s, then you need to eliminate these unnecessary steps and procedures. Once you do that then you can ensure making what your customer needs. It can reduce cost and save you a lot of time which will eventually result in a lower price.

Create Flow

The next of the 5 principles of lean production is to create the flow of the procedures so that everything goes smoothly. For that, companies can break down the procedure into steps through departmentalization and training their employees accordingly.

Establish Pull

For effectiveness and improvement at the workplace, there is a need for Pull-based system. In a pull-based system, inventory is delivered just in time, so that the company could manufacture the products for a specific quantity that is required. The purpose of this system is to save manpower, inventory, and resources. In this way, whatever you are making will be timely, in small quantity, and in better quality which will meet the needs of your customer. This also limits any type of waste in a company.

Pursuit Perfection

Once you have done all 4 of the above-mentioned principles, then it is time for the fifth principle which is about pursuing perfection. It is the most important of them all as it ensures continual improvement in an organization. Every employee in every department should try to achieve perfection that can satisfy their customer’s value. This doesn’t go for just one time only, but employees should try to achieve perfection doing a little bit better every day.

Implementation of The 5 Principles of Lean Production

In order to do better in an organization, you must require a framework. A Lean production method provides a framework that is effective and efficient. But first, you should let the people understand the idea behind it by introducing it to them. Employees should be ready to accept this. Start small and eventually take it to every level in your organization. Cut out the inefficiencies and fill the gap with creative steps that are in demand for achieving customer value worldwide. All five of these principles encourage procedural flow and continuous improvement in the organization. With these 5 principles of lean production, a company can achieve a competitive edge, profitability, low cost, and more value.