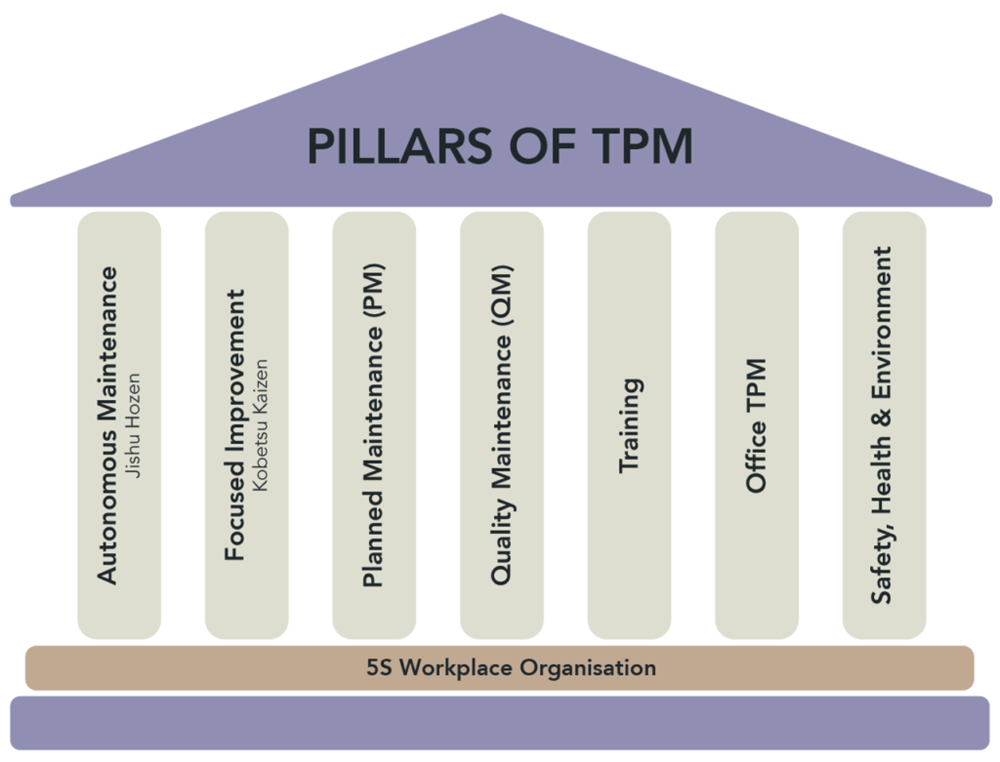

Total Productive Maintenance (TPM) is a way of keeping and improving the reliability of manufacturing and quality systems by means of procedures, equipment, machines, and human resources that increase the value of business in an organization. Basically this system emphasizes on maintaining the entire equipment’s in their best working condition to stay away from breakdowns and interruptions in the production processes. Lets continue with defining the 7 pillars of TPM.

7 Pillars of TPM

Focused Improvement

The first of the 7 pillars of TPM is known as Focused Improvement. It offers a planned, team-oriented approach to compel removal of particularly known losses in any procedure. This pillar pursues a planned set of milestones associated with the Plan, Do, Check, Act (PDCA) cycle, which can be applied for expansion activities of any extent or difficulty in a business entity. In addition to increasing efficiency, decreasing errors and enhancing security performance because of removing failures, this pillar makes sure that the chosen system is constant and repeatable to ensure viability with a sustainable approach.

Autonomous Maintenance

The second pillar of TPM is known as Autonomous Maintenance. It practices a planned approach to boost the personnel skill levels in order to make this possible that they can know, handle and develop their equipment as well as procedures. By applying Autonomous Maintenance the ‘Overall Equipment Effectiveness (OEE)’ can be improved by decreasing performance failure and rising the availability of equipment. Moreover, there will be improvement in employee commitment and competence levels that is quantifiable.

Planned Maintenance

The third of the 7 pillars of TPM is Planned Maintenance with the objective of realizing zero breakdowns. It pursues a planned approach to launch a management system that increases the dependability of equipment in cost effective way which works best for the business. In general, the maintenance team directs the activities of the Planned Maintenance. The main advantage achieved by following this system is the decline in breakdowns, which results in decreased expenditure and better efficiency level of machines.

Training and Education

The fourth pillar of TPM is known as Training and Education. This pillar focuses on assuring that employees are properly trained in the skills that are considered essential for their individual development as well as for the successful TPM implementation corresponding to the goals and objectives of the business entity. An analysis is made to assess the existing skills that are compared against the desired requirements and a training plan is devised to fill the identified gaps. It is quite helpful in producing a corporate and professional atmosphere that makes best use of the employee’s potential and respond in a productive way to the varying corporate environment, management innovation and modern technology development.

Early Management

The fifth pillar of TPM is known as Early Management with the basic objective of employing latest products and procedures with upright ramp up and reduced lead time for development. Generally, Early Management is implemented subsequent to the first four pillars because it is developed on the basis of the learning derived from other teams of the pillars, adding advancements into the next generation of manufactured goods and equipment plan. Effective deployment of this pillar can bring decreased lead times for merchandise and system introduction, better Overall Equipment Effectiveness and the capacity to offer in volume at the true quality from manufacturing start-up.

Quality Maintenance

The sixth pillar of TPM is Quality Maintenance with a basic objective of guaranteeing defect conditions at zero level. This is possible by understanding and managing the process communications between 4M which comprises of manpower, machines, material, and methods that may possibly allow defects to happen. The main focus is to avoid defects from being manufactured in the initial stage, instead of fixing difficult inspection methods to discover the defect once it has been created. This pillar decreases the quality budget, due to the fact that waste caused by inferior quality, revision, and customer objections, and inspection requirement are decreased.

Office TPM

The last of the 7 pillars of TPM is Office TPM and focuses on each and every area that offers administrative and maintenance tasks in the business entity. Office TPM implements the main TPM principles in removing waste and damages occurring from these units. It makes certain that all procedures encourage the improvement of production methods and that they are finished at ideal budget. This pillar provides many advantages for the business by excluding damages in the administrative structures of the entire business as well in the comprehensive supply chain. At different sources we can also find another eighth pillar known as Safety Health Environment. Its basic focus is on zero accident, zero health loss, and zero fires. This pillar facilitates in producing a harmless work environment that is not ruined by our method or practices. In order to produce awareness among the workforce, different competitions such as quizzes, safety slogans, posters, drama, and the like can be planned at fixed intervals.