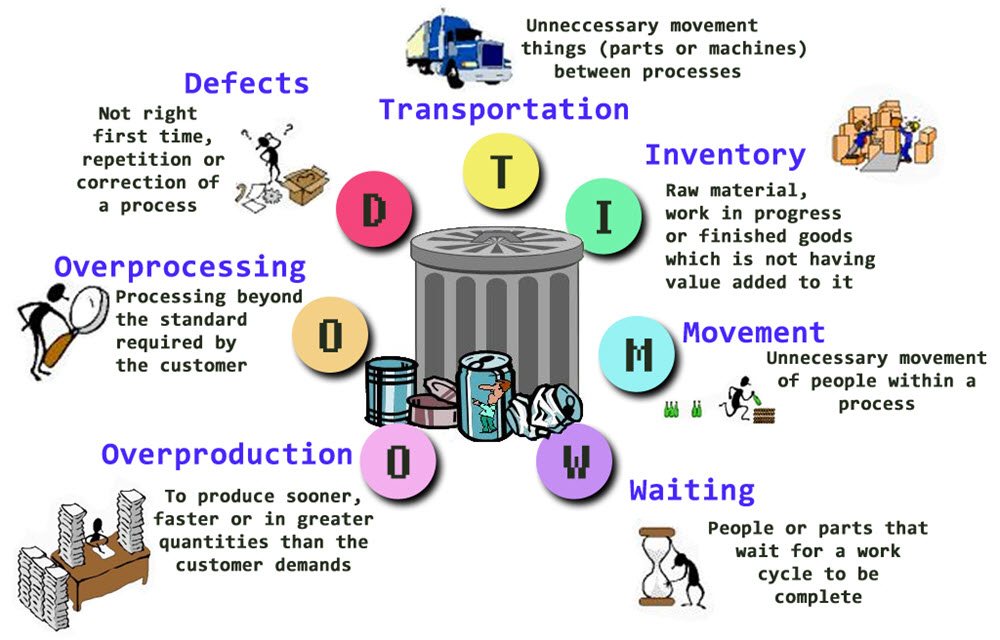

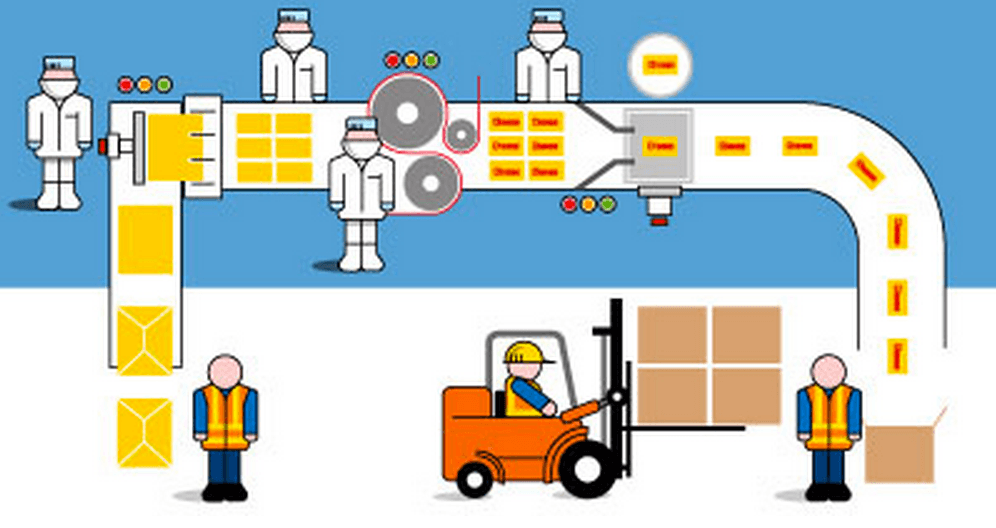

Timwood Lean Refers to the 7 Waste of Lean

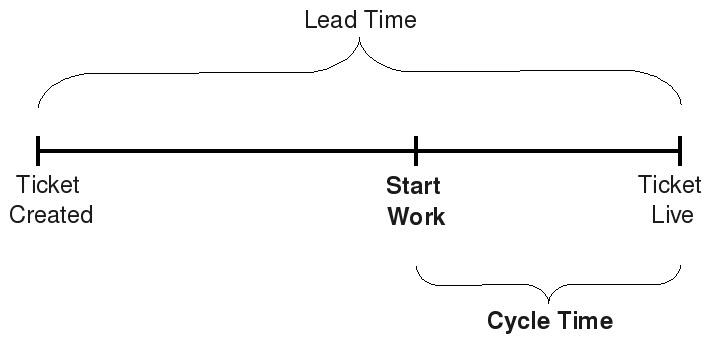

Managing a competent business entity covers lean manufacturing which is a technique for reducing waste that influences manufacturing strategies, production, and customer relationships. This method is useful in minimizing costs, boost profits, improve lead times, and increase customer satisfaction for an organisation. The term of "TIMWOOD" stands for: Transport, Inventory, Motion, Waiting, Over-processing, Overproduction, [...]