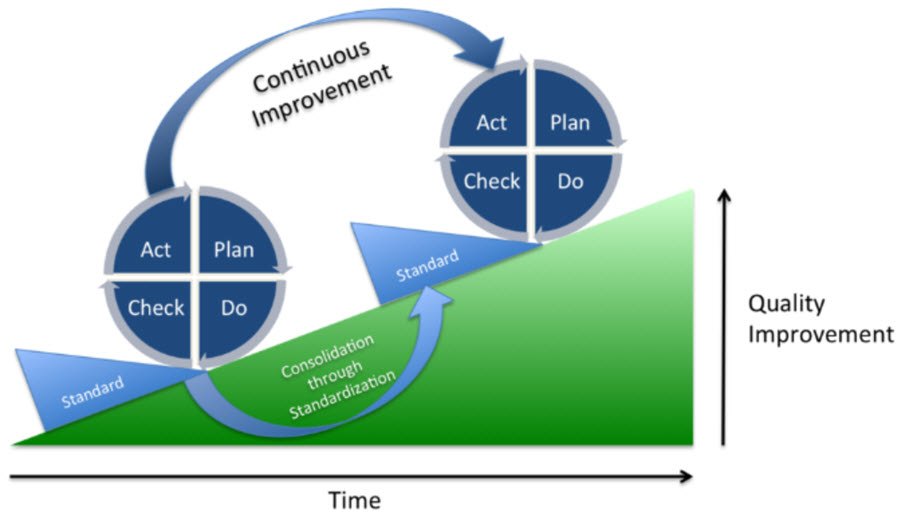

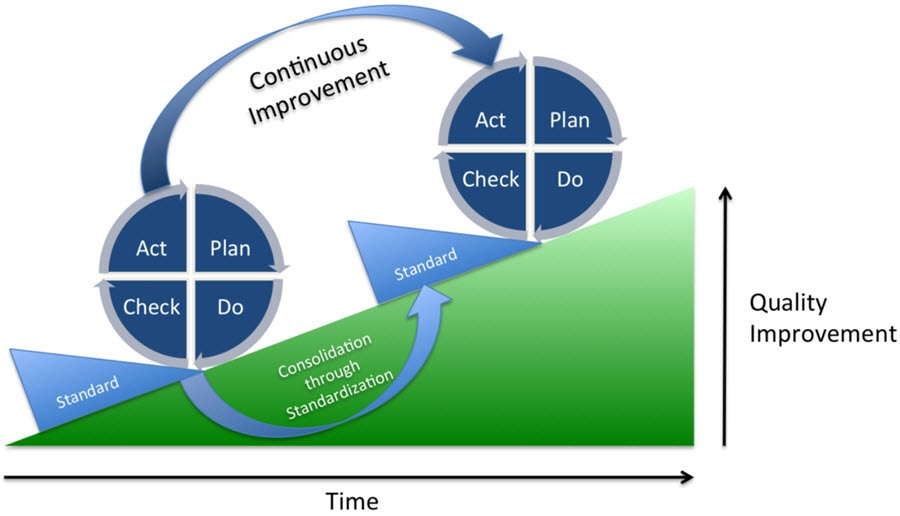

PDCA Cycle of Continuous Improvement Explained

PDCA cycle is a potent tool for continuous improvement that is able to improve anything. It looks effortless, but it is an exceptionally powerful tool. The more you use this tool, the more improvement you will witness. So, PDCA stands merely for Plan, Do, Check, and Act. Some people refer PDCA as PDSA, and [...]