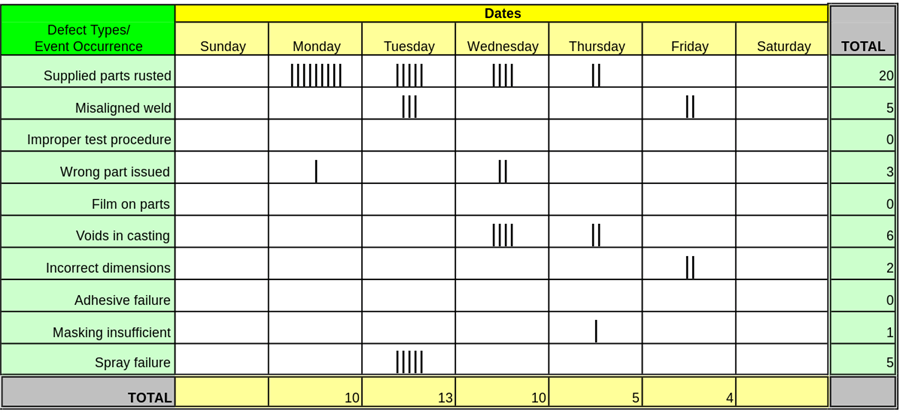

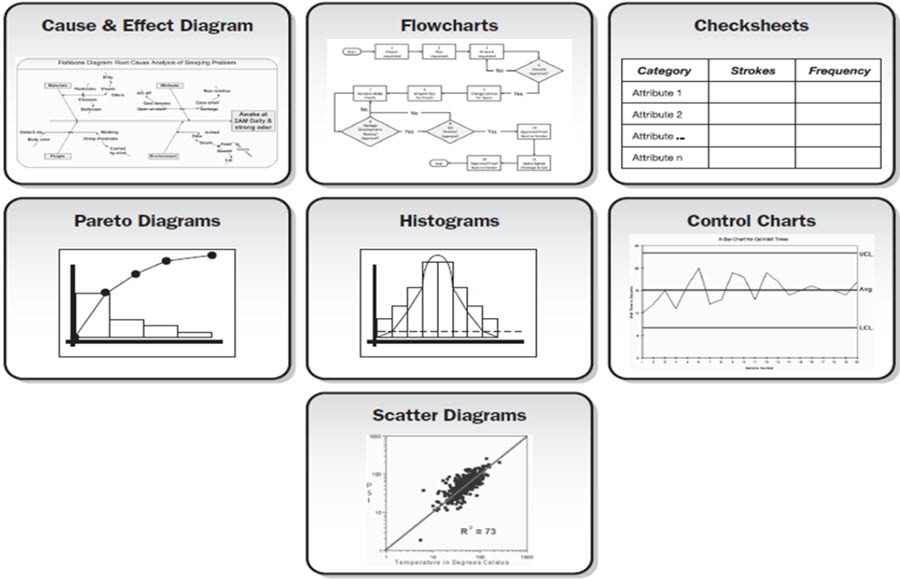

What Types of Check Sheet Are Used in Manufacturing

The check sheet is the effective, efficient, and simple way to depict data and information. A check sheet is a structure table, metrics table, or form for gathering data to analyze it. When the information or data are gathered in both quantitative and qualitative data, then the check sheet remains check sheet, but it [...]