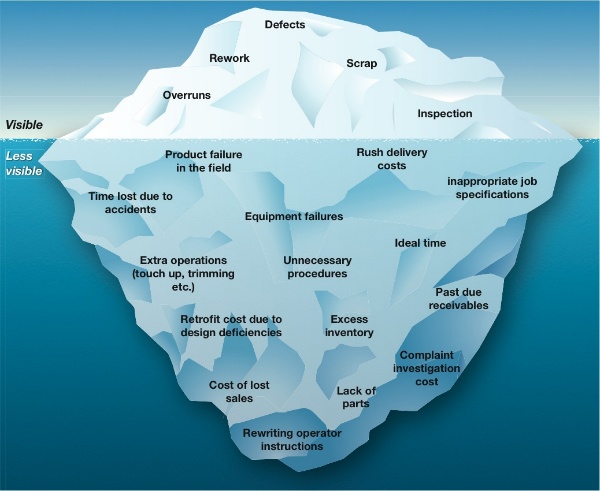

Cost of poor quality (COPQ) is described as the cost of flaws in ongoing operation or product. It is the primary economic research that is done for Six Sigma or lean manufacturing. It is utilized to validate inception of a new project. Cost of poor quality includes the cost of junk, revised and restored materials and all activities associated with this. These costs can arise from either problem in operation of the manufacturing line or by the utilization of supply chain. Hence, it is significant to find out its origin prior to the calculation. Once all the associated cost for an unwanted event or waste materials is understood you can look at how to calculate cost of poor quality.

How to Calculate Cost of Poor Quality

For calculating COPQ it is important to follow the following steps;

- First of all it is essential to find out nature of waste that might be present in the process.

- Then recurrence of waste production should be determined.

- Determine cost per part, incident or time.

- Estimate COPQ by following calculation.

Cost of poor quality depends upon the failure cost that includes external failure cost as well as internal failure cost. A following formula is used to determine cost of poor quality;

Cost of poor quality (COPQ) = Internal failure cost (IFC) + external failure cost (EFC)

Where,

IFC= junk cost + remodeled cost

EFC= restored product cost + product rescission costs + warranty cost

The external and internal failure costs are caused by supplying the substandard product as well due to the weaknesses in the operations.

Factors Affecting Failure Costs

There are many factors that affect external and internal failure costs. External failure cost is affected by;

- Inimical notoriety situations

- Unsettled client’s complaints

- Feeble organization intercommunication

- Environmental noncompliance

Whereas the internal failure cost is affected by

- Substandard materials preparation

- Shortage of materials

- Unexpected machinery intermission

- Review of materials and goods

- Finished goods redesigning

COPQ estimation is not just the amount spent on inspectors or calculation of waste materials. In fact it is calculated in form of cost prevention, income probabilities strayed or incompetence of personnel.

Cost of Poor Quality and Supply Chain

Costs of poor quality of singular suppliers who participate in the supply chain have an additive effect on cost of poor quality of end product shipped by original equipment manufacturers (OEM). Therefore, to reduce the cost of poor quality companies have to work passionately with the suppliers. A charge-back system is implemented by many Original equipment manufacturers for cost recovery; in this case the supplier is charged an extra amount due to late delivery or supplying non compliant product or service. This charge back system pushes the supplier to improve quality and fix flaws by identifying root cause.

How COPQ Can Be Reduced

The implementation of quality management system (QMS) can significantly reduce cost of poor quality by providing with interspersed reformatory actions. There is a need of resolving any inadequate event as soon as they appear such as variations, noncompliance, or customer complaints. After identification of a quality issue, it is important to find out the root cause firstly. After the root cause identification corrective actions should be taken to resolve the issues immediately.

A web based quality management system makes it easy for the suppliers to participate in quality management. The suppliers usually utilize a single plant for all the OEMs and they just cannot install a new plant for every single OEM. Therefore the OEM has to trust the supplier’s processes and quality information provided to them. In the web based QMS the supplier provides all the information about product quality to the OEM before shipping the product. In this way OEM can review all the product details and can take specific corrective actions before the product gets out of the supply chain. This results in lower COPQ.

Although there are many ways and methods of calculating cost of poor quality, the best is to always calculate it by a standard method every time. It is easier to detect trends and improve quality of product or service due to this standardization and centralization of COPQ calculation in an organization.