How to Create an Efficient Flow Production

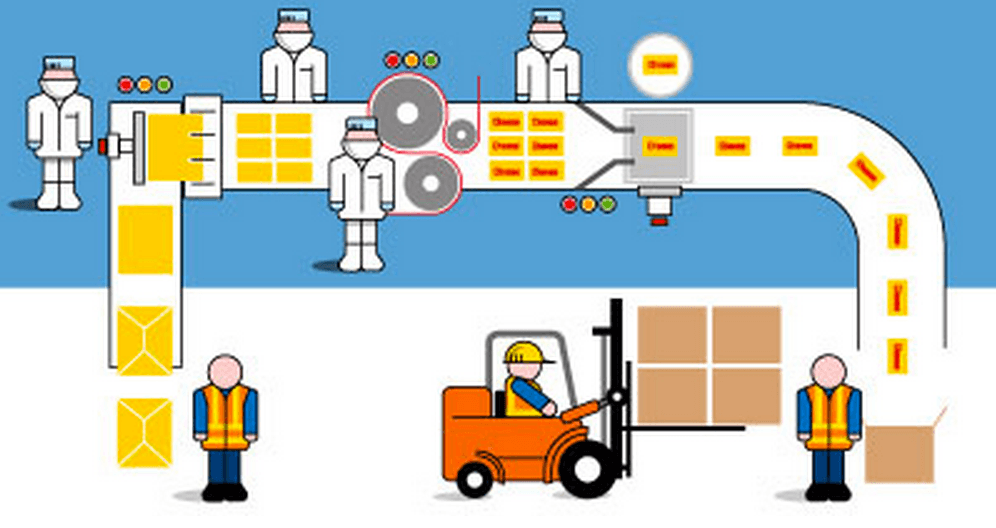

Every company needs a sound flow production plan to maximize productivity. However, for a complex process that covers a wide variety of activities effective production planning is required to ensure that equipment, materials and human resources are available where and when they are needed. Production planning is like a guide that it assists you [...]