Visual Factory Techniques and How to Implement Them

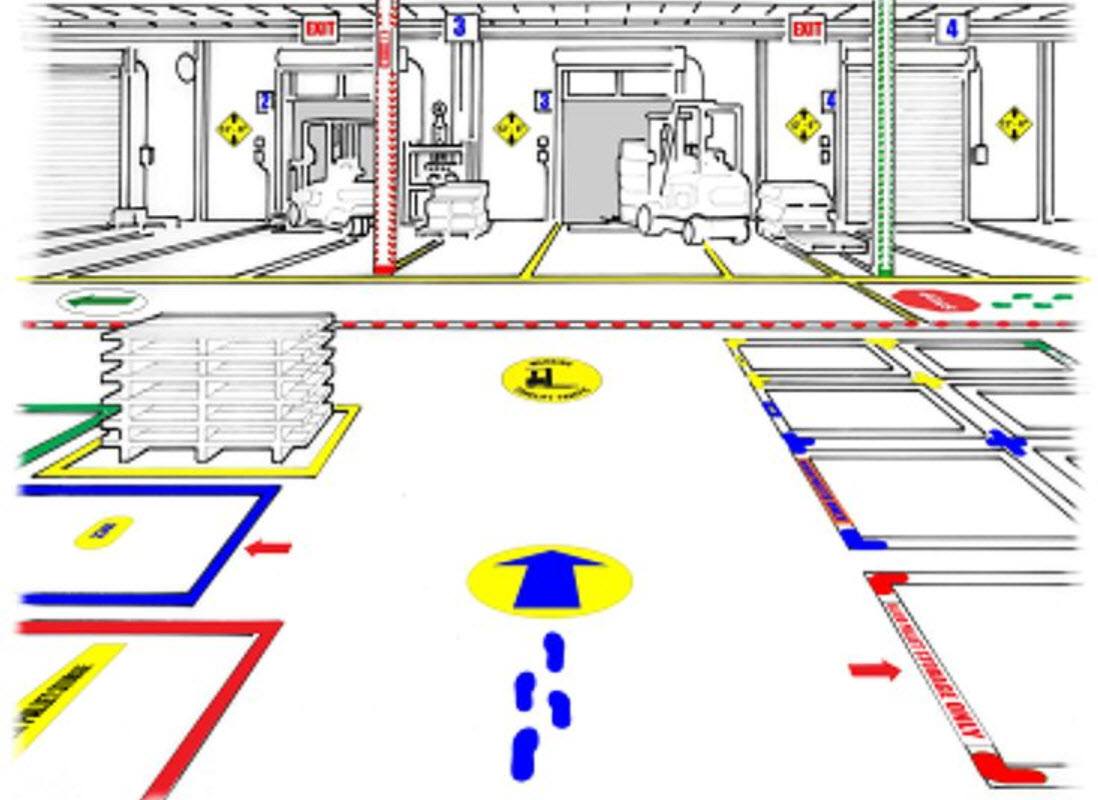

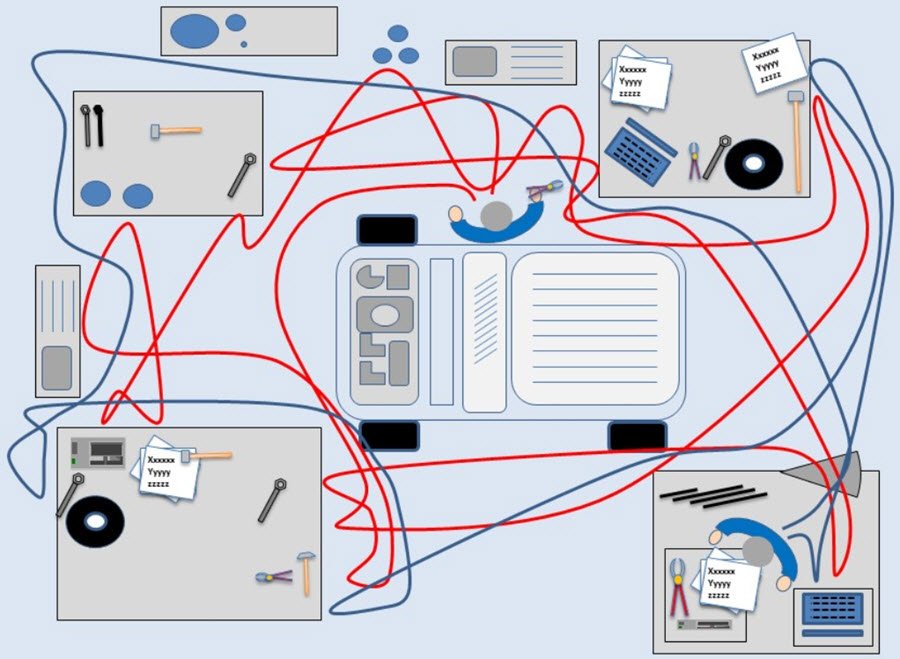

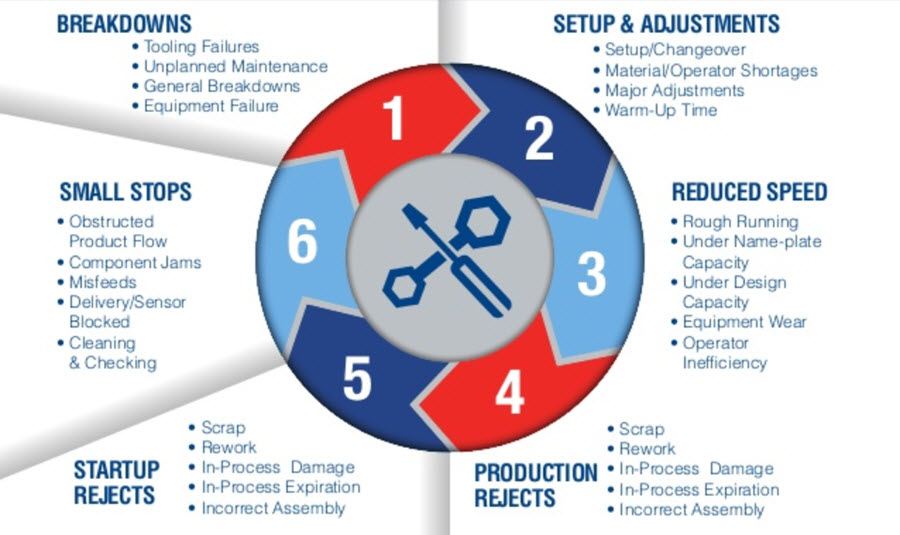

The term “visual factory techniques” is a concept of lean manufacturing processes founded on visual information all over the working place of a business entity. It employs a coordination of communication tools for information sharing at the time and place it is considered necessary. Through visual controls it is probable to communicate without words [...]