Firstly, let me explain to you what measurement system analysis (MSA) is. In short then measurement system analysis (MSA) is a mathematical and experimental process which determines how much variation the measurement system contribute to the overall process variability.

Measurement System Analysis Terminology

There are a few terminologies that are used in the measurement system analysis. Below I am going to explain all the common terminologies so that it is easier for you to understand the measurement system analysis.

Discrimination

There is a smallest detectable addition between two measured values. When you use a gauge, there is a minimum count or least value which you can easily measure with the related gauge.

Accuracy

You need to understand the fact that there is a difference between the observed average and the true average. Usually, the true average might be obtained by applying a more precise measure instrument. The very minute when there appears a difference between the average value and the true average, it suggests that your system isn’t accurate.

Stability

Here we look at the difference that can be seen in the average of the two sets of measurements at least, which is measured over the time. Like when an object is measured at time (T1) and after time (T2) the average values are completely different.

Elements of MSA

The key element in the measurement system analysis is the measurement itself. There are a total of 5 parameters to examine in an MSA. They are:

- Bias: It is also denoted as accuracy, in simple terms, it is a measure of the distance that is between the average value of all the quantities and the “True” or “Actual” value of the part.

- Linearity: It is a degree of the consistency of Bias over the whole range of the measurement tool. The amount of Bias also changes over the entire range of use.

- Stability: It refers to the ability of a measurement method which produces the very same values over a period of time when it is measured with the same sample.

- Repeatability: It assesses whether the same evaluator can measure the similar part numerous times with the same measurement tool and get the same value.

- Reproducibility: It assesses whether the dissimilar evaluators can measure the similar part with a similar measurement tool and as a result obtain the same value.

In the measurement system analysis, we rely on the data as much as we can. Along with that, we use various techniques to comprehend the difference within measuring devices. For example the variation that is brought into the measurement system by environment and people. There are a few useful ways for the evaluation of how much error is being contributed by the gauge and how much error is coming from an individual. For an MSA you identify numerous types of errors and how every error can be removed and avoided.

Measurement Error

This error means that there is a difference between the true value and the value that is measured. It mainly depends on two things.

- The kind of tool that we are using

- The person using the tool

That is why whenever you use an instrument, always keep in mind that there can be possibilities of a measurement error that is present there.

Now you might ask how much measurement error is really acceptable.

Well according to AIAG (2002), a common rule of thumb for the measurement system acceptability is:

- Under 10 percent error is acceptable.

- The errors that range between 10 and 30 percent mean that the system is satisfactory, along with depending on the significance of application, cost of repair, cost of the measurement tool and other factors.

Errors that exceed 30 percent are considered to be unacceptable. It means that you should make improvements on your measuring system.

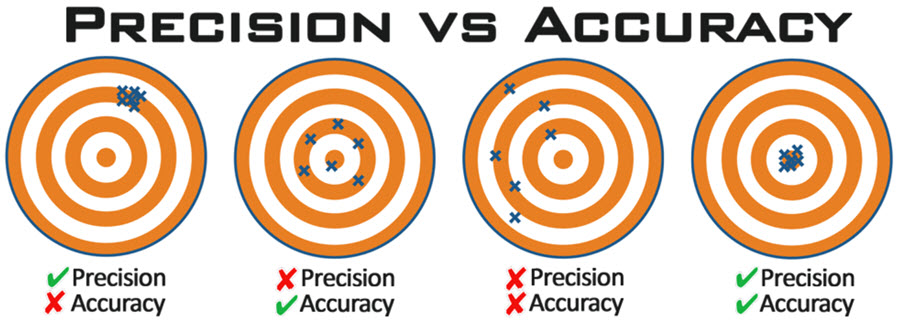

Measurement Precision and Accuracy

The main purpose of measurement system analysis is to make the measurement system successful by evaluating the precision, accuracy, and stability.

- All the measurements are denoted accurate if they tend to revolve around the actual value of the sample that is being calculated. The accuracy is achievable when the calculated value has little difference from the actual value.

- The measurements are accurate if they vary from each other by only a small value.

Use Consistent Measurements

Imagine that there is a call center and it has auditors that evaluate the quality of every phone companion’s call, and all the phone associates are then graded on their quality, which also impacts their paycheck. If every auditor is inspected to a dissimilar standard, then without a doubt, there will be a lot of difference in the measurement technique. Therefore it is crucial to use consistent measurements.

So there you have all the input on the Measurement Systems Analysis. I hope that the article has helped you in understanding what an MSA is and how it is conducted.