The United States was a leading player in the world of manufacturing during the 1950 and 1960s. The main competition existed only between the businesses in US. For the reason that there was not much competition, US manufacturing backed down from statistical quality control and management standards for certification were not considered compulsory. In the 1970s, Mil-I-45208 inspection standard and Mil-Q-9858A quality program standard were developed by the US military and emphasized that the proper standards must be met by their suppliers. There were inspectors in the military that used to visit or take part in production plants to make sure the systems were all set.

Acknowledgement of the Importance of a Quality Management System

The basic awareness that a quality management system QMS might influence a product’s quality was initially presented in the 1970s. Moreover, it wasn’t introduced by the International Organisation for Standardization, instead of that a few huge establishments like Ford and the Ministry of Defense, who issued quality management standards maintained by their own organisations. The leading influence upon the fast recognition of this idea was by the Ministry of Defense, since it used to deal with a large number of various suppliers. It was obligatory for an organisation to fulfill the necessities of their quality management standards to trade with them.

The First BS 9000 Issue

In 1971 the first standard published in UK was by the BSI (British Standards Institution), the BS 9000, this standard was specially planned for the electronics industry. Moreover, they published the BS 5179 and 5750 as well; both standards were established very closely around the standards of the Ministry of Defense. For the first time, the responsibility of quality assurance was transferred to the supplier from the customer, instigating the practice of third party assessors. The world progressed towards international trade during the 1980s. Nations and industries needed to agree on quality assurance standards. The US again moved towards to the quality management systems and statistical control due to the international trade.

The First ISO 9001 Within ISO 9001 History

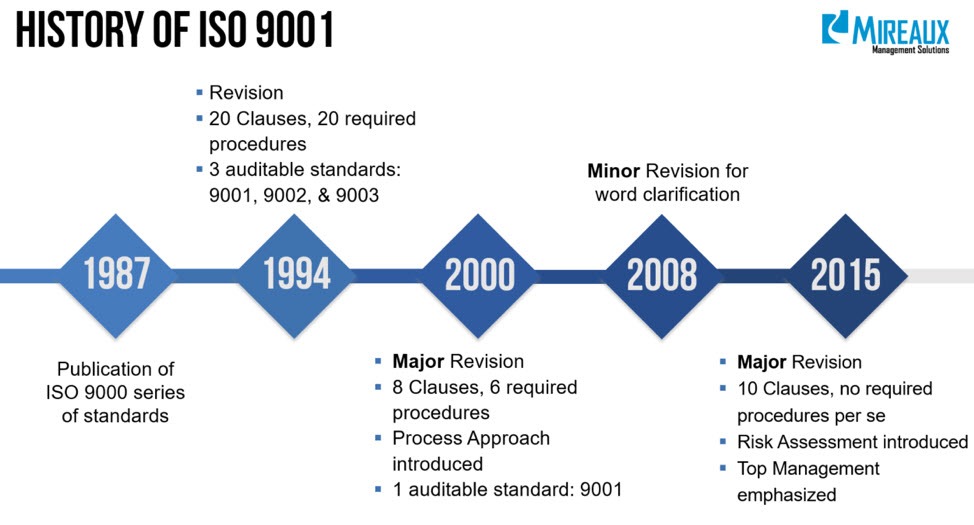

In the same era, there was a lot of improvement in the American companies because of total quality management theories. In the 1980s, the UK’s standards were implemented by the International Organisation for Standardization into their international parameters and certification qualifications. In 1987, the initial ISO 9000 was published. The ISO 9001:1987 possessed a restricted structure with twenty conditions, however it emphasized on meeting the procedures requirements and the big-image of forming a superior course was slightly vanished. The same issues of imposing conformity were found in ISO 9001:1994. The business establishments were having a hard time below the weight of rules and principles, assembling large manuals that usually withheld the process instead of facilitating it.

The ISO 9001:2000 Issue

In addition to that, from the time when the ISO 9001 was announced, the ISO 9001:2000 observed major modifications. It fought the complications and pursued to make a standard that concentrated on progressive development. The running dictated the documentation instead of large manuals and documents ordering the administration of a QMS. This third edition within the ISO 9001 history sought to prolong the importance that the ISO 9001 was regarding the formation of a quality management system by means of process performance parameters. The documentation was substantiation of the process being running successfully.

Recent Version in The ISO 9001 History

At the present, ISO 9001 is one of the most commonly known standards at global level being implemented by business entities and corporations internationally as a symbol of belief, quality and high standards. A lot of organisations will not purchase from a company which is not ISO 9001 certified. The ISO 9000 standards are established on the notion that a systematic quality assurance program delivers assurance in the products or services and the management team of an organisation.

Furthermore, ISO has two types of quality management standards including the requirements and guidelines. Collectively these two types of quality standards compose the ISO portfolio of Quality Management Standards. Requirements are the official prospects that should be met if an organisation wants to be certified or registered formally and they are obligatory. In contrast, guidelines are just recommendations and suggestion which are non-mandatory. Formerly ISO comprised of three groups of quality requirements: ISO 9001, ISO 9002, and ISO 9003. But, at this moment there is just one standard: ISO 9001 2015.