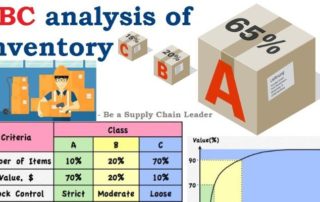

ABC Analysis Steps for Inventory Management

What is ABC Analysis When we talk about ABC analysis steps in light of Inventory optimization in supply chain, it means a method of inventory categorization in which items are divided into three classes A, B and C. A indicates the most important items and C indicates the least [...]

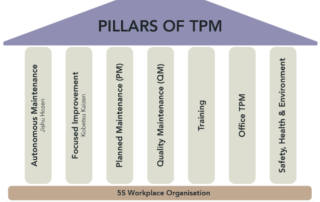

What Are the 7 Pillars of TPM Used in Lean

Total Productive Maintenance (TPM) is a way of keeping and improving the reliability of manufacturing and quality systems by means of procedures, equipment, machines, and human resources that increase the value of business in an organization. Basically this system emphasizes on maintaining the entire equipment’s in their best working [...]

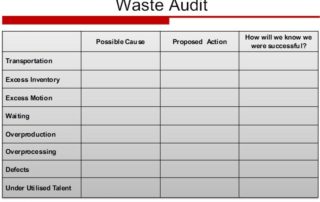

How to Create an Effective Waste Walk Checklist

You ever feel like there is something wrong, but you can’t put your finger on it? Well, before you can fix the problem, you need to recognize it first. The longer you stay in that one place, the more you’ll struggle in seeing the problem, which we call “waste.” [...]

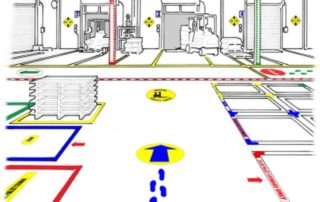

Visual Factory Techniques and How to Implement Them

The term “visual factory techniques” is a concept of lean manufacturing processes founded on visual information all over the working place of a business entity. It employs a coordination of communication tools for information sharing at the time and place it is considered necessary. Through visual controls it is [...]

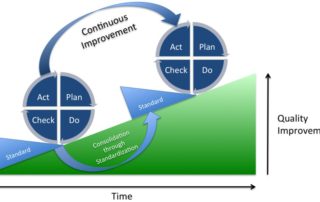

Standardized Work as a Lean Process Improvement

Standardized work is used as a tool for preserving quality, productivity and safety at high levels. It is described as work in which the order of job essentials has been planned efficiently that are followed by workers on constant basis. Standardized work is a procedure in which kaizen is [...]

Manufacturing Changeover Single Minute Exchange of Dies (SMED)

One of the essential elements of Lean involves a system of fast changeover. When the changeover time of equipment is quicker the downtime is less. One must consider that “Downtime” is the description of the eight deadly waste of a manufacturing setting. The basic tool to quick changeover system [...]