Heijunka Production Leveling Used in Manufacturing

In lean manufacturing Heijunka means “production leveling”. In business of any nature, fluctuations can occur due to changing customer’s demands and needs. Therefore, in order to smooth out the production process, implementation of heijunka production leveling is really important. Heijunka promotes just in time manufacturing. It improves the efficiency [...]

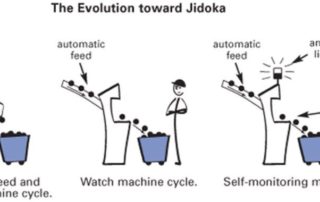

What Is Jidoka Lean Manufacturing

Jidoka is considered as one of the most important pillar of Toyota production system, the other being just-in-time manufacturing. It is a Japanese term, which means “Autonomation”. Jidoka focus mainly at quality from the core. For every organization, quality is the most important tool to achieve success through excellence [...]

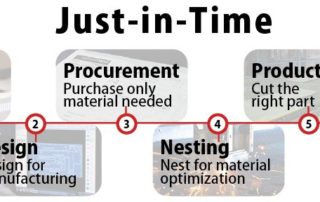

Advantages of Just in Time Manufacturing

Just-in-time manufacturing is the manufacturing tool in which products are made according to customer’s demands, for example, when they need it, in what quantity and the quality parameters etc. it is also recognized as “pull production system” as the production is triggered by the arrival of an order. It [...]

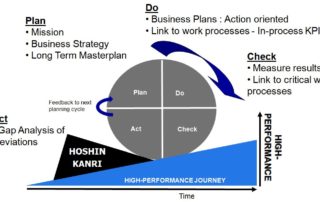

How Is the Hoshin Kanri Method Used in Manufacturing

The Hoshin Kanri method tries to get each and every employee pulling in a similar direction and at the same time. It attains this by aligning the aims of the company (Strategy) with the plans of middle management (Techniques) as well as the work performed by all staff (Operations). [...]

What Is Takt Time Calculation and How to Do It

“Takt time is the maximal time taken by a product to be manufactured so that it meets the customer demands.” It is derived from a German word “baton” that means “Pulse”, “Pace”, “Rhythm” or “beat”. For example, if a company needs 20 minutes to complete a product that meets [...]

Generating a 5S Checklist for Manufacturing

The 5S practice is a technique used to establish and maintain quality environment in an organization. The original concept was developed by Osada in the early 1980s. The acronym 5S stands for the five Japanese words seiri (organization), seiton (neatness), seiso (cleanliness), seiketsu (standardization), and shitsuke (discipline). These techniques [...]