Heijunka Used for Leveled Scheduling

What is Heijunka? In the corporate world, executives and managers have to be conscious of the fact, that it takes some effort to maintain a steady work flow. Basically, Heijunka is a lean methodology used for dropping the irregularity in a manufacturing process and reducing the possibility of overload. [...]

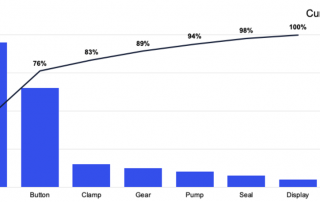

How to Draw a Pareto Chart and What It Will Show

Pareto chart is simply a basic quality tool to help identify frequent defects, complaints, or other factors as part of a data analysis study. It is a deceivingly simple concept which can have huge benefits when analysing data. The Pareto owns its existence to Vilfredo Pareto. The famed economist [...]

Driving and Restraining Forces in Field Force Analysis

In our life, we often come across a point where we have to make a tough decision for ourselves such as starting a new chapter or embrace a change. At that point, we sometimes find ourselves helpless, clueless and with no solution to the problem. While assessing if and [...]

How to Implement Kaizen in an Organization

Kaizen is continuous improvements where changes are required in organization’s processes. The approach could either be a one time implementation or a step by step change over time. One of the top benefits provide by Kaizen is that it is continuous and not a time limited process. Kaizen offers [...]

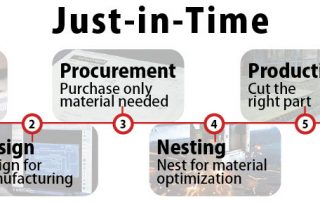

Just in Time Manufacturing Examples for Production

Manufacturing within companies have evolved over several years and Toyota has been one of the key players to revolutionize manufacturing through adopting just-in-time (JIT) as part of their lean manufacturing system. The methodology of this generally customed to minimize and decrease the production timeline and only produce what is [...]

The Kanban Implementation Steps for Manufacturing

For a successful implementation of Kanban within manufacturing, you must ensure you have set right environment for it. The further you are from ideal situation; the more work is required to implement this system. Following are ideal situations which should be considered during Kanban implementation steps: Keep constant prediction [...]