Value Stream Mapping Tutorial for Lean Manufacturing

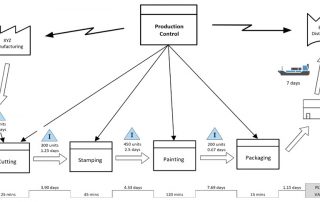

Introduction Value stream mapping (VSM) is a tool used in lean manufacturing to minimize the waste (increases efficiency and value production). Lean manufacturing is fully about minimizing waste and adding value to your products and services. Value stream mapping starts with analyzing the current state which is how the [...]

Training Needs Analysis Questions for Employees

Training needs analysis (TNA) is not a new concept in the corporate world and it has been used for decades for the skills enhancement of employees. Basically, it is an organized process that can be used by any organization for defining the training needs of its employees which also [...]

How to Use a Kanban Production Control System

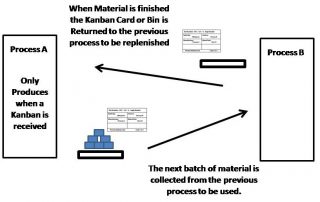

A Kanban production control system is a visual system used to control production as a part of Lean Manufacturing or Just in Time (JIT). Being part of pull system, it can manage to control what to produce, how much to produce, and when to produce it. The aim of [...]

Implementing Cross Training Employees

In the current climate business organizations can’t take the risk failing irrespective of the industry, just because their key player was lost at a critical stage. Cross training employees plays a vital role, so that losing one of them won’t cause an end to our organization. Basically, cross-training is [...]

How to Generate and Use a Process Control Chart

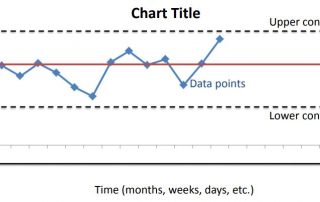

What are Process Control Charts? Basically ‘Process Control Charts’ are where process data (outputs) are plotted out in the form of graphs or charts in a time-ordered cycle and it is a focused run chart. In simple terms we can say that it is a graph which is used [...]

What is the Andon System and how is it Used

What is Andon System? Basically, an Andon System is part of Lean manufacturing which is designed to keep operators and managers on the alert about any occurring issues in real time and take counter measures without any delay. In simple terms, it can be defined as a visual tool [...]