How to Effectively Use Time and Motion Study Techniques

A time and motion study is utilized to observe work effectiveness through the observation and timing of assignments. It can enable you to see where your day could be more productive, saving you time and vitality. You can perform one on yourself or watch someone else while conducting a [...]

How to Implement 5S in the Workplace

5S in the work place is one of the primary tools that can be implemented in an organization as a starting point to change the culture of an organization to a continuous improvement culture. A 5S implementation characterizes the principal guidelines to wipe out waste and keep up an [...]

Benefits of Business Process Improvement

As the business competition grows day by day, expectations also change and there is demand for new methodologies and technologies. It increases the demand to improve your business processes. Therefore, Business Process Improvement (BPI) is the most compelling and adequate way to create ongoing improvement in your business. It [...]

Guide on Value Stream Mapping Steps to Take

The value stream map is a chart which illustrates and also analyses the various steps that are involved in the delivering of a particular service or manufacturing of a product. Whenever an individual maps the present state of a process from the start to the end, areas which are [...]

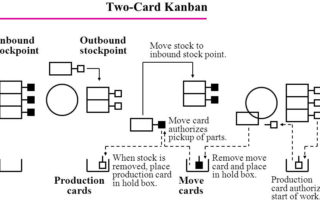

How to Implement a Two Card Kanban System in Manufacturing

Kanban can be well defined as ‘demand scheduling.’ In processes which are controlled by kanban’s, the manufacturers manufacture products based on the actual usage instead of the estimated usage. The kanban system replaces the usual daily or weekly production schedule. This schedule is substituted with predetermined decision instructions and [...]

Kaizen 5S for Process Improvement within your Organization

The 5S is the acronym of five Japanese words which stands for Seiri (sorting), Seiton (setting in order), Seiso (sweeping), Seiketsu (standardizing), Shitsuke (sustaining). In the mid-1950s, 5S was first used in Japan in the manufacturing sector. 5S is the first step to continuous improvement. 5S implementation ensures continuous [...]