What are Quality Objectives?

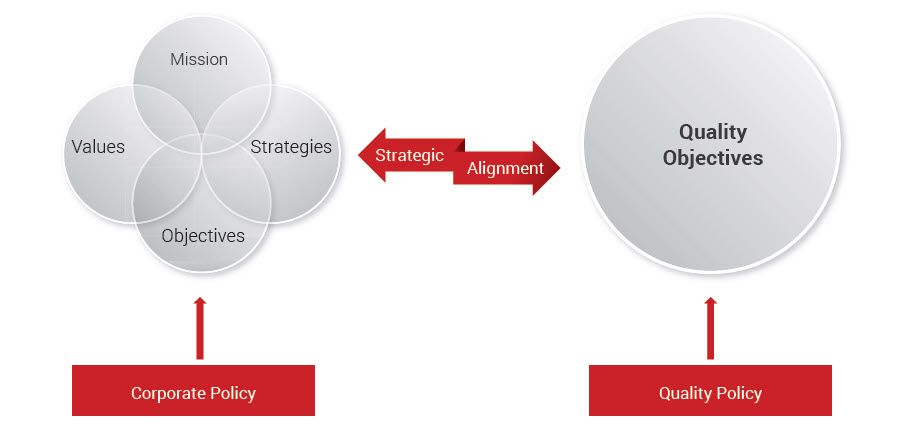

TQM (Total Quality Management) is a customer-focused process that drives continual improvement of business operations. The goal is to ensure all associated employees work toward common goals to improve the products or services provided by the organization. It is an ideal way for business activities to be carried out by the organization as well as its employees. In the manufacturing industry a positive impact has been seen on business outcomes attributable to these processes. In order to be effective, the quality policy of a quality management system should be aligned with the objectives. Basically, quality objectives are measurable goals that is intended for increasing the value of an organization’s processes, products, and services. Establishing a set of quality objectives is a basic process for quality management. It is responsibility of the senior management to make sure that an effective quality system is ready for accomplishing the quality objectives.

Why Quality Objectives are Important?

It is required by ISO 9001 that quality objectives are established at all relevant organizational levels and functions. An organization must be aware of the fact that the way in which quality objectives are created and managed will put a huge impact on the company’s performance. When the quality objectives are established in an effective way, then they will lift strategic improvements across the entire organization. Likewise, it will considerably increase the prominence of the quality management system in the company. On the other hand, if quality objectives are not established properly, then they’ll only turn out to be a pointless effort for data collection. Therefore, quality objectives for a manufacturing company, should mainly depend on what an organisation does and the product and services it provides to customers.

The Quality Objectives for a Manufacturing Company

- An important quality objective for a manufacturing company is to ensure the ‘Accuracy of a Process or Service’. For instance, it can be an inventory management process aiming to improve its forecasting accuracy as it wants to decrease its out of stock articles.

- In the same way, ‘Product Completeness’ can be used as an objective by a manufacturing company. The company which offers a different product variety, can work with a target to deliver the maximum products variety. In order to make it measurable the manufacturing company can set a benchmark product selection in contrast to the product category offered by its competitors.

- Furthermore, the ‘Customer Service Objective’ is usually pointed as ambitious goals where customer experience is demonstrated as a clear picture. Normally, customer satisfaction is the basic tool to measure this objective. A manufacturing company can monitor data related to customer perception as one of the performance measurements, this way the organization is in a position to see if the customer requirements are fulfilled or not.

- Additionally, the objective of ‘Increased Service Levels’ holds paramount value for a manufacturing company, as it will eventually result in increased revenue. The service level is based on the company’s ability to meet consumer demands. An organization with a service level of 80 percent meets its consumer demands 80 percent of the time.

- In addition to that, one more significant objective is ‘Continual Improvement’. Now it is expected that most of the manufacturing companies that manufacture a product want to improve their product continually. In this regard, it’s important to remember that the objective of continual product improvement doesn’t imply a completely new and value-added product. In most cases it refers to continually enhancing process efficiencies and product quality. This quality objective also meets the additional requirements of other quality objectives. It focuses on customer satisfaction because of an improved product quality. In the same way, the number of complaints and product returns will fall.

- For a manufacturing company another important objective is ‘Ensuring Effective Supply Chain Management’. Supply Chain Management covers different approaches which are implemented to integrate manufacturers, suppliers, and stores in an efficient way. In this way the product is manufactured and distributed in the right quantities, at the right time and to the right locations. This objective helps a company to save its cost and meeting customer requirements.