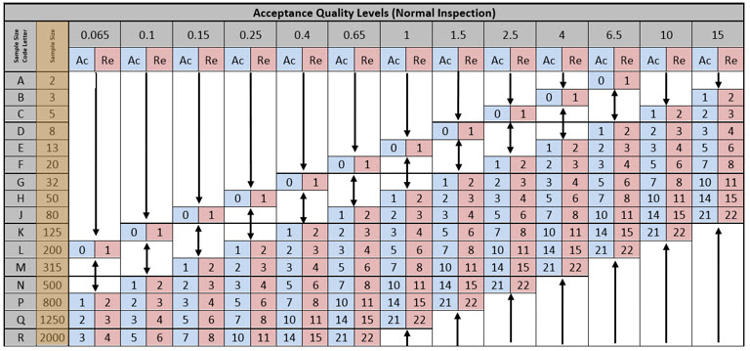

Sampling plans assists us in defining our sample size or we can say the items number that need inspection for every single lot of received material. When an organization decides on a receiving inspection sampling plan, such as the usually used ANSI/ASQ Z1.4, it is establishing a standard for the defects percentage that it is ready to put up with for all measured features. Now, the percentage of the defects can be 0 for the product features holding maximum critical value. An organization may perhaps select a different percentage which is commonly between 2.5 to 4.0% for less critical features. The name of this level is known as Acceptance Quality Level (AQL).

When it comes the receiving inspection sampling plan we must know that every plan is designed to offer a quantified risk for producer as well as receiver. Nevertheless, it is in the favour of the receiver’s that the average number of items inspected (ANI) must be kept to a minimum as the inspection cost is low in that case, however at the same time no compromise the quality of the product or service. With regard to ANI we can observe different forms of sampling plans. The most commonly used attribute sampling plans include the single-sampling plan, the double-sampling plan, and the sequential-sampling plan. Moreover, similar plans have been designed for the quality variable measures as well.

The Types of Receiving Inspection Sampling Plan

Single Sampling Plan

First of all, let’s consider the single-sampling plan. Basically it is an assessment rule depending upon the outcomes of one random sample from a lot to receive or reject the lot. Its process includes choosing a random sample size (n) and checking all items. The complete lot is accepted by the receiver when the defects numbers does not go beyond a definite acceptance number (c). If any defects are observed in the sample then they are either fixed or given back to the producer. Although, as compared to the other plans this form of sampling plan is not complicated and can be used easily, but generally we can see a higher ANI in the end.

Double Sampling Plan

When double sampling plan is used for our receiving inspection sampling plan, there two sample sizes (n1 and n2) and two acceptance numbers (c1 and c2) selected by the management in a double-sampling plan. The lot can be accepted or rejected by the receiver and the final decision is made on the basis of the first sample. In order to implement this sampling plan, a random sample of size n1 is selected by the receiver. When the defects number is below or the same as (c1), the lot is accepted by the receiver. In case of defects number exceeding (c2), the lot is rejected by the receiver. The receiver chooses to select a second sample of size n2 when the defects number lies between c1 and c2. The lot is accepted by the receiver when the combined defects number in the two samples is below or equivalent to c2. The lot is rejected by the receiver otherwise. Certainly, by using double-sampling plan we can considerably decrease the inspection costs in relation to a single-sampling plan for lots with an extremely small or great amount defective since it can be chosen once the first sample is taken. On the other hand, the sampling costs can be exceeding compared to the single-sampling plan when it the final choice has to be made requiring two samples.

Sequential Sampling Plan

Furthermore, an additional enhancement of the double-sampling plan is the sequential-sampling plan. In this sampling plan items are chosen by the receiver randomly from the lot and they are inspected in sequence. Based on the collective results to this point, a choice is made to reject or accept the lot or to carry on the sampling process when each time an item is checked. The expert plots the overall defectives number in contrast to the cumulative sample size, and the lot is accepted by the receiver when the defectives number is below a definite acceptance number (c1). The lot is rejected by the receiver in case the number is larger than a different acceptance number (c2). More to the point, an additional item is inspected when the number lies anywhere between the two. For the sequential-sampling plan the ANI is normally lower than any other method of acceptance sampling which means reduced inspection costs. On the whole, this form of sampling plan can decrease the ANI up to 50 percent of that essential by a similar single-sampling plan and, as a result provides the opportunity of saving considerable inspection expenditures wen it is selected as our receiving inspection sampling plan.

Risk Based Sampling System

It is important to consider that if we implement a risk-based sampling system as it then really can support us in consuming less time and a smaller amount of money spent on the inspection of high-quality raw materials, as it makes us more confident knowing that they are already good. It gives us the opportunity of identifying raw materials with dissatisfactory performance and suppliers depending on their inspection state. A classic risk-based inspection program takes account of a sampling system with a proper sampling strategy. A key difficulty in risk-based inspection is that it is difficult to track sampling systems.