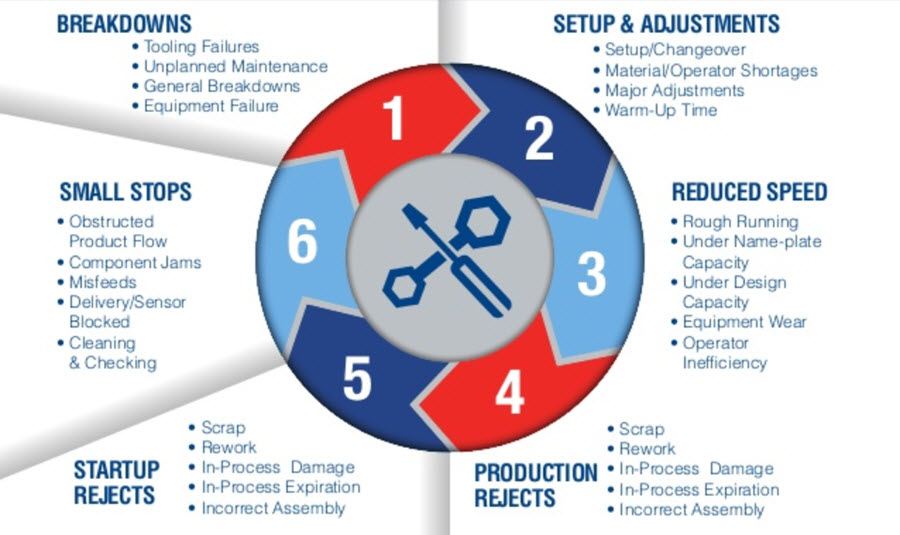

In the light of TPM (Total Productive Maintenance) and OEE (Overall Equipment Effectiveness) program one of the key objectives is to decrease or get rid of what is known as the “Six Big Losses” that indicates the most common causes in productivity failures within manufacturing. Its framework comprises of the losses that fall in the three categories of Availability, Performance and Quality. Each category is divided into two groups where

- Availability losses includes: Equipment failures/unplanned stop, set-up and changeovers/planned stops

- Performance losses includes: Idling and minor stoppages and reduced speed

- Quality losses includes: Scrap/rework and startup losses.

Categories of Six Big Losses

Availability Losses

The category we will discuss from the six big losses is the availability loss. When we consider the availability of a process, it is decisive to understand the reasons of that loss and to describe the time spent during unplanned stops and identifying the time as well that takes to complete any planned setup/changeover events. Decreasing the time spent for unplanned and planned events rises the available running time to manufacturing. For “Equipment failures or unplanned stops” it is vital to spot equipment malfunctions or downtime into separate experiences and to assess the time allocated for each event to know the reasons. An imperative step in identifying with the particulars is gathering and recording these incidents on the charts or into production software.

When it comes to “Set-up and changeovers” the biggest cause of downtime is usually changeover events and is normally referred to as “make ready” or “setup” depending on the type of business. Changeovers can be enhanced to the highest degree and are tackled with the help of using SMED (Single-Minute Exchange of Dies) programs. However, Changeover events are planned in the absence of target time and no visibility of real-time, this time turns out to be tricky to develop over time. For longer changeovers the main reasons are main adjustments, tooling adjustments, warm-up time, cleaning, and quality inspections. When real changeover times are weighed against desired goals, improvements can be prepared to decrease setup times and increase machine accessibility.

Performance Losses

In addition to that, when we look at the category from the six big losses which is called performance losses “Idling and minor stoppages or small stops” includes Idling and minor stoppages that in general causes other expensive troubles. This is one of the simplest areas for enhancement and in majority cases; taking precautionary action entails uncomplicated modifications in working processes instead of pricey equipment expansions. On the other hand, to accomplish long-term and durable improvements in this vicinity, information must be recorded as the minor stops takes place promptly and can simply be ignored or considered as only component of the procedure. Recording this to specify the time and the causes for stoppages is the place to begin.

For “Reduced Speed Operation” the objectives for producers are to advance the operation speed. Nevertheless, a balance has to be attained between the most advantageous efficiency of an individual equipment piece and product quality manufacture for a procedure. By having the capacity to distinguish real-time line speeds can present a spectacular consequence on performance. For reduced speed the common reasons consist of dirty machines, damaged equipment, lubrication, environmental circumstances, worker experience, and usual startup and shutdown techniques.

Quality losses

The last category of the six big losses is quality loss which covers “Scrap and Rework”, however being familiar with the quantity of the loss is not sufficient alone. In order to improve performance exact signs and the causes of the loss are essential. Analyzing and reporting of poor quality is incorporated into the quality system and precautionary actions are applied to improve the part as well as the process. For “Startup Losses” in all startup routines there are losses in creating a procedure. In order to get a line running at its maximum running speed there is a strong need that the operators set up the line and losing product is usually part of this procedure. To be aware of estimated losses having better visibility of the startup circumstances for the line is significant. For start up the common causes consist of ineffective changeovers, wrong settings, and equipment wear or startup cycles.

There is no denying in the fact that for continuous improvement, efficiency can be made to develop competence, decreasing costs and increasing profitability if we consider the “Six Big Losses” framework as a guidance system.